Welding robot; a versatile robot

you can automate your production line so that it works 24/7. mechanizing production lines can significantly affect the growth, precision, and speed of your business. Today, a significant portion of various industries from kitchen and electrical appliances to automotive and aerospace industries require welding. Welding robots can perform welding operations at much higher speeds and with much greater accuracy than human labor. A welding robot can increase productivity and lower production costs by working continuously and without rest while maintaining high-quality work. At the same time, using robots for welding prevents the health risks associated with human labor. Given the intense competition in various industries, investing in welding robots can put you several steps ahead of your competitors. However, if your competitors outperform you in this area, the way to make up for the gap is to use industrial robots again.

In this content, we want to talk about welding robots and review some products of one of the best and biggest companies that manufacture welding robots. Therefore, if you are also looking to develop your productivity and reduce production costs, and need various types of welding in your manufacturing lines, stay with us until the end of this article.

What is a welding robot?

A welding robot is a type of industrial robot used for automated welding processes. Some of the earliest robots used in industry were welding robots. In 1962, Joseph F. Engelberger and George Devol created a robot called the Unimation 001, which was used for spot welding on an assembly line at General Motors factory.

Unimation 001; the first robot that was used for welding applications.

It took almost two decades until the 1980s for welding robots to gain popularity in large industries such as automotive manufacturing. But soon the advantages of robotic welding were recognized so gradually smaller industries also began to use welding robots.

As robotic technology advanced, robots became more advanced and cost-effective. At the same time, competition between companies to automate their production systems and increase production while reducing costs led to welding robots finding their way into smaller industries such as household appliances and electronic devices such as televisions, refrigerators, and more.

The benefits of welding automation were quickly widely recognized. Recent advancements such as advanced control and laser and 3D vision have greatly enhanced the capabilities of robots.

8 industries that use robotic welding

These robots can be used for any industry that requires welding, but some of the most common industries include the automotive industry, steel industry, aerospace industry, iron smelting, aircraft manufacturing, factories producing metal parts, electrical and household appliance production, etc. The price of a welding robot can vary depending on its application. Robotic welding has many high-value applications, which we have only touched on here.

Seven robot welding methods

A robotic welding cell can perform a wide variety of welding techniques. Below we will discuss various robotic welding methods:

1. ARC welding

This method is one of the oldest and most common welding methods performed by industrial robots, also known as electric arc welding. In this method, heat is produced up to 6,000-7,000 degrees Fahrenheit, which melts the metals and thus joins them together. As a result of the process and cooling of the metals, a strong connection is created between them.

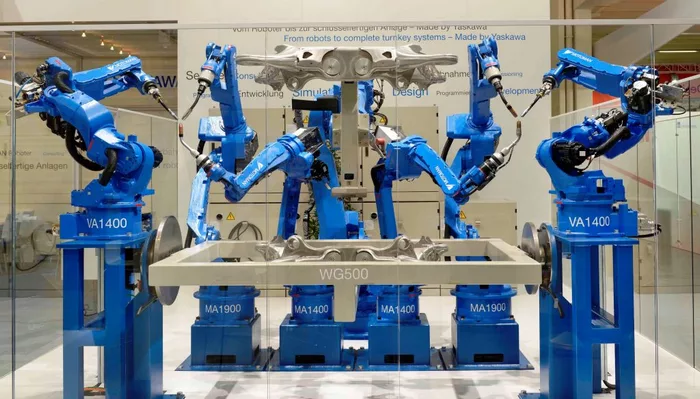

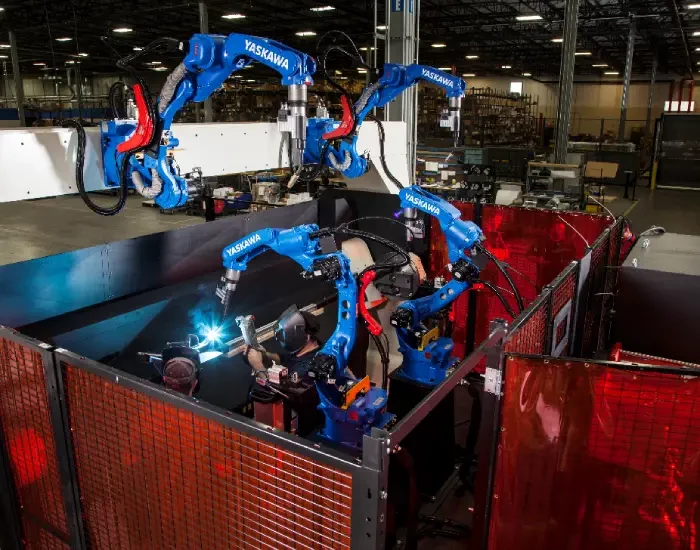

Arc welding with Yaskawa Motoman robots

2. Spot Welding

Spot welding is a method used to join thin metal sheets together at a specific point. This method is widely used in the automotive industry. In this type of welding, an electric current passes through the welding joint between the two metals, and with the high heat generated, the two metals are joined together.

Spot welding with Yaskawa Motoman robots

3. CO2 Welding Robot

This method, called metal arc welding, is one of the fastest and easiest methods that use metal deposition. A wire is continuously fed into the heated arm, and as a result, it melts. This method provides a large amount of molten metal to connect a base to another part.

This method is most commonly used in processes where there should be no interruption. It is clear that humans are not capable of welding regularly and without interruption, and this method comes to the aid of humans.

4. TIG Welding

In industries where welding needs to be done with high precision, the gas tungsten arc welding method, known as TIG welding, is practical. It is actually a type of electric arc that passes through the tungsten electrode and the metal base and connects two pieces of metal together.

TIG welding using Yaskawa Motoman Robots

Tungsten inert gas (TIG) welding is mainly used in cases where spot welding is needed and continuity during welding is not very important. It is also used for thin metal connections. The smoke produced from tungsten is often carcinogenic, and for this reason, the use of robots in this method is necessary. Although this method has been abandoned in other countries, it is still used in our country.

5. Laser welding

Laser welding is used when welding with a large number of parts need to be done with high precision and speed, such as small jewelry parts, medical equipment, etc. In this method, a laser device directs the laser beam to the parts through an optical fiber. This welding method is useful in cases where welding needs to be done remotely.

Laser welding by Yaskawa Motoman robots

6. Plasma welding

Plasma welding is mostly used when there is a need to quickly change the state of parts and connections in an industry. This method has the highest degree of flexibility, and the operator can easily change the gas speed passing through the nozzle and the temperature.

7. Aluminum welding

Aluminum welding is done using the arc welding method. The well-known welding methods for aluminum are MIG and TIG welding.

A robotic cell with two spot welding robots on an ArcWorld

A robotic cell with two spot welding robots on an ArcWorld

Welding Robot Cell

Industrial robots are usually designed to be programmable and usable for a wide range of applications. Therefore, a robot needs equipment that can be separately mounted on it to perform the desired activity. For example, a Yaskawa AR or GP series robot can also be programmed for cutting applications. Of course, this requires the installation of suitable equipment on the robot. This means that packaging robots have their own grippers, and a welding or cutting robot has its own specific equipment. Each type of welding, such as spot or electronic arc welding, also has its own specific equipment that can be installed and mounted on the welding robot. A collection of equipment and robots that perform a specific task is called a robotic welding cell.

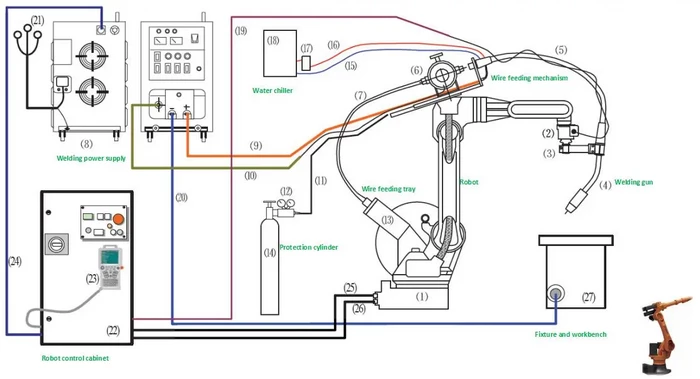

Welding Robot Components; from Power Supply to its Base

Just like any other robot, welding robots have their own specialized components. Here are some of them:

Power Supply

The power supply can be considered as the heart of the welding system. It provides the necessary power to weld the metal parts, and its installation requires three-phase electricity.

The interface is connected to the power supply through the interface controller so that they can monitor the power supply settings, robot speed, and more.

Interface Cable

The interface cable is used to connect the power supply and robot controller.

Water Cooler

Some welding processes require a source of cool water, which is provided by the water cooler.

Wire Feeder

The wire feeder delivers the welding wire to the torch so that it matches the voltage and current of the power supply.

Feeder Bracket

The feeder bracket is used to mount the wire feeder on the robot.

Tube

The tube is the communication cable for the wire feeder.

Torch Breakaway

The torch breakaway cuts off the torch in case of contact.

Insulation Disc

Insulation discs are used in welding robots to provide insulation between the welding torch and any mechanical structure or components that may be in close proximity to the torch during operation. The insulation disc helps prevent electrical arcing and damage to these structures or components, which can be expensive to repair or replace.

Torch Cable

The torch cable is used to connect the torch to the wire feeder.

Torch Neck

The torch neck is, in fact, the welding torch.

Wire Holder

The wire holder delivers the wire to the wire feeder. It can be in the form of a barrel or a spool.

Wire Guide

The wire guide is installed between the wire feeder and the wire holder.

Linear Tracks

Linear tracks allow the welding robot to operate multiple robots with increased access.

Power Supply Base

The power supply base is used to install the welding power supply.

Robotic welding; advantages of using it

There are many factors that make companies and factories interested in robotic welding, including:

Cost reduction and cost-effectiveness

Good appearance and high-quality consumable parts

Achieving fast and highly accurate results

High productivity

High safety

Prevention of serious injuries such as explosion, blindness, electric shock, etc.

High operational speed

Prevention of human error

Contribution to the Environment

Energy consumption reduction

Ability to work around the clock and every day of the week.

Robotic welding; disadvantages of using it

Just like any other technology, robotic welding has many advantages, but it also has some drawbacks that may overshadow its benefits in some cases. Here are some of its disadvantages:

Companies that use robotic welding benefit from lower transportation costs. However, if you want to invest in operators and equipment individually, you will be at a disadvantage.

Robots are more reliable than humans, but it should be noted that humans can react to abnormal conditions that robots cannot. When a robotic welder needs correction, a lot of time must be spent reprogramming, which makes the project longer.

Configuring the robotic arm takes a long time, which is not ideal for small projects.

Robotics cannot make independent regulatory decisions.

Robotic welding is difficult in some specific locations such as internal tanks, ship hulls, and pressurized vessels.

Dependency on robotic welding can be very problematic when technical problems arise with the robots.

Setting up the initial needs for robotic welding requires a high cost. Although in the long run, by increasing efficiency and reducing production waste, robots compensate for the initial cost and greatly improve work efficiency.

How to work with welding robots?

Like any other task in the industry, using a welding robot has different methods depending on the operation it is used for. In the following, you will become familiar with the types of these methods.

Welding robots are a step towards reducing the time of welding projects. As mentioned above, it is necessary to consider various parameters when choosing a welding robot. The choice of the best welding method also depends on what we want to use it for. However, some of the most important parameters are:

The first and most important factor is the industrial application that the industrial robot we need is intended for.

The second factor is to look at the physical specifications of the robot. In simpler terms, how many arms do we need for the robot?

And the last factor is the amount of weight that the robot is supposed to withstand. What should be the length of the robot arm?

By considering the above factors and the mentioned methods, we hope you can make the best decision. In this article, we have tried to explain briefly about robotic welding and everything you need to know. The price of welding robots is high, and it is better to do enough research before buying or contact our experts for more information.

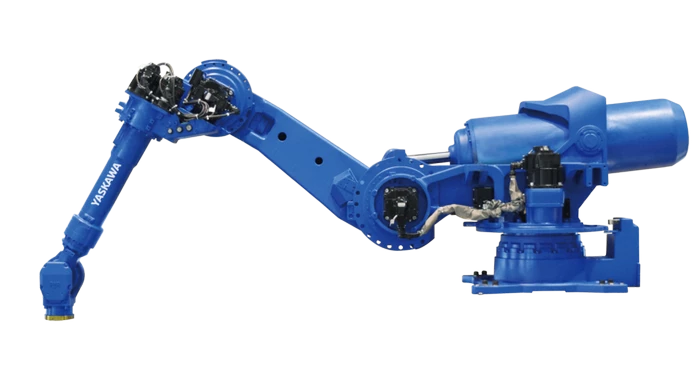

Types of Yaskawa Welding Robots

Yaskawa is one of the best robot manufacturers in the world and a leading company in the robotics industry. Welding robot is one of Yaskawa’s products for which they are famous.

Considering the different types of welding and the various applications that can be expected from a welding robot, this company introduces and produces different models of welding robots. Generally, Yaskawa’s specialized welding robots are produced in three series, which we will introduce below.

Models and types of Yaskawa welding robots:

1. AR series

Yaskawa’s Motoman AR series has high speed and accuracy for arc welding and thermal cutting and also supports all types of welding and their equipment.

These robots, with high accessibility (from 700 to 3124 millimeters), especially when combined with Yaskawa positioners and gantries, can weld any type of parts in any conditions and dimensions. The AR series has six models. We will examine their specifications and details below.

AR900 model

The Motoman AR900 is a compact welding robot with high accuracy in routing and high stability.

This model of the AR series has a payload of up to 7 kilograms and the reach is up to 927 millimeters. With this Yaskawa model, you can expect high-quality results in arc welding.

These robots can be a suitable substitute for cobots when there is a need for welding large parts or high speed. They also support a wide range of Yaskawa’s robotic welding functions.

This Yaskawa robot model provides excellent performance in small and compact cells, such as the RS Micro and HS Mini models.

Model | AR900 |

| Number of axes | 6 |

Payload | 7 kilograms |

| Reach | 927 mm |

Repeatability | 0.01 |

| Weight | 37 kilograms |

Power supply | 1 KVA |

| Mounting options | Ceiling, wall, floor |

AR700

The Motoman AR700 also provides precise routing and high working stability similar to the 900 model. This model can handle a useful weight of 8 kilograms, which is heavier than the 900 model but its reach is 727 millimeters which is lower than the 900 model. This robot provides excellent-quality welding for small parts.

Motoman AR700

Motoman AR700

The Yaskawa Motoman AR700 model also supports a wide range of welding functions, making it a suitable replacement for human welding robots in cases of high workloads or short cycles.

Model | AR700 | |

| Number of axes | 6 | |

Payload | 8 kilograms | |

| Reach | 727 mm | |

Repeatability |

| |

| Weight | 35 kilograms | |

Power supply | 1 KVA | |

| Mounting options | Ceiling, wall, floor |

Model AR1440

The six-axis Motoman AR1440 robot is our most popular robot for arc welding. This model is actually the global reference for robots in the field of arc welding, thermal cutting, and any program involving routing. With a combination of precision, performance, and efficiency, This model has put Yaskawa in a leading position in the field of robotic welding for decades.

The AR1440 model enables you to achieve the best welding results in the toughest conditions.

With a payload of 12 kilograms and a reach of 1440 millimeters, this model is suitable for any type of professional welding equipment, any process, and any type of workpiece. The bent arm design and hollow arm structure allow integrated torch cabling and avoids collisions.

Model | AR1440 |

| Number of axes | 6 |

Payload | 12 kilograms |

| Reach | 1440mm |

Repeatability | 0.02 |

| Weight | 150 kilograms |

Power supply | 1.5 KVA |

| Mounting options | Ceiling, wall, floor |

AR2010

The MOTOMAN AR2010 is an ideal choice for robotic applications involving arc welding, cutting, and path-related tasks. This robot has been a superior choice for welding robots over the past few decades due to its ability to blend precision, performance, and functionality seamlessly. Even under the toughest conditions, the AR2010 can deliver optimal welding results.

The robot is capable of handling a large payload of up to 12 kg and has an extensive working range of 2,010 mm. It is suitable for a wide variety of professional welding equipment, processes, and larger workpieces. The design of the robot’s arm is curved and has a hollow structure, enabling the integrated torch cabling and avoiding collisions.

Model | AR2010 |

Number of axes | 6 |

Payload | 12 kilograms |

Reach | 2010mm |

Repeatability | 0.03 |

Weight | 260 kilograms |

Power supply | 2 KVA |

Mounting options | Ceiling, wall, floor |

AR3120

If you’re looking for a robot with a reach of over 3 meters for welding or cutting large and complex workpieces, the six-axis MOTOMAN AR3120 could be your perfect choice. Its precision, path performance, and functionality have made MOTOMAN welding robots stand out over the past few decades. Even under challenging conditions, the AR3120 can deliver excellent welding results. The robot’s arm has a curved design and hollow structure, which enables integrated torch cabling and reduces the risk of collisions.

Model | AR3120 |

Number of axes | 6 |

Payload | 20 kilograms |

Reach | 3124mm |

Repeatability | 0.03 |

Weight | 560 kilograms |

Power supply | 2 KVA |

Mounting options | Ceiling, wall, floor |

AR1730

The MOTOMAN AR1730 robot is specifically designed to handle heavy arc welding or cutting equipment. It offers a combination of precision, top-notch path performance and functionality that has made MOTOMAN welding robots stand out over the years. With the AR1730, you can achieve excellent welding results even in challenging conditions. The robot’s bent arm design and hollow arm structure facilitate integrated torch cabling and prevent collisions.

Model | AR1730 |

Number of axes | 6 |

Payload | 25 kilograms |

Reach | 1730mm |

Repeatability | 0.02 |

Power supply | 2 KVA |

Mounting options | Ceiling, wall, floor |

GA series

The MOTOMAN GA series is a precise robot model suitable for laser applications that require high accuracy, including laser cutting, remote laser welding, or cladding. With its ability to handle heavy loads, the robot can effectively control large laser heads and perform tasks such as creating circles, curves, and straight lines with outstanding results.

GA50

The MOTOMAN GA50 robot is specifically designed to perform tasks that require a high level of precision and accuracy in movement, such as 3D laser cutting or welding. With a payload of 50 kg and a reach of 2,038 mm, this robot can handle large workpieces using commonly sized laser heads.

Thanks to its advanced Sigma-7 servo drive technology and optimized precision gearboxes, this robot has excellent positioning and path accuracy while also being mechanically stiff. Additionally, the MOTOMAN YRC1000 high-performance robot controller offers various programming functions, interfaces, and communication options that enable seamless integration of the robot.

Model | GA50 |

Number of axes | 6 |

Payload | 50 kilograms |

Reach | 2035mm |

Repeatability | 0.01 |

weight | 855 kg |

Power supply | 4.5 KVA |

Mounting options | floor |

SP series

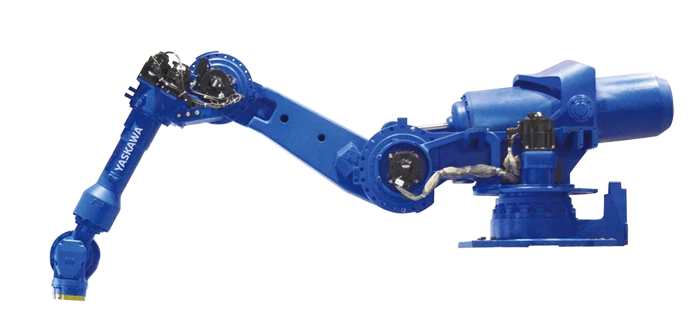

The MOTOMAN SP Series comprises spot welding robots that are versatile and robust, with the added capability of handling tasks. Their slim design allows for easy placement in restricted spaces while offering a higher maximum range of motion.

These robots are capable of carrying payloads ranging from 80 to 250 kg, making them suitable for a variety of spot welding guns and technologies, including servo-controlled welding guns with robotic gun balancing.

SP80

The MOTOMAN SP80 is the smallest robot in the MOTOMAN SP series and is designed for spot welding and handling tasks. It can handle a payload of up to 80 kg (including the C-adapter) and has a working range of 2236 mm, making it suitable for servo-controlled lightweight welding guns.

This robot is ideal for compact spot welding lines with a high robot density in car body construction, welding small subassemblies in an economical manner, and for saving space by installing it on a positioner.

With the compact and powerful MOTOMAN YRC1000 controller and the latest Yaskawa Sigma-7 servo drive technology, the MOTOMAN SP80 has high dynamics, energy efficiency, and exceptional cycle times.

Overall, the MOTOMAN SP80 has a slim design and a large working range, making it a highly versatile and efficient robot for spot welding and handling applications.

Model | SP80 |

Number of axes | 6 |

Payload | 80 kilograms |

Reach | 2236mm |

Repeatability | 0.03 |

weight | 630 kg |

Power supply | 4 KVA |

Mounting options | Floor, ceiling, roof |

SP100

The MOTOMAN SP100 is a small, versatile robot designed for spot welding and handling tasks. It can support a payload of up to 100 kg (including the C-adapter) and has a working range of 2236 mm, making it ideal for servo-controlled lightweight welding guns.

This robot is well-suited for compact spot welding lines with high robot density in car body construction, as well as for welding small subassemblies economically. Additionally, it can be installed on a positioner to save space.

With its compact and powerful MOTOMAN YRC1000 controller and Yaskawa Sigma-7 servo drive technology, the MOTOMAN SP100 has excellent dynamics, energy efficiency, and cycle times.

Overall, the MOTOMAN SP100 is a highly adaptable robot that can handle spot welding and handling tasks with precision and efficiency.

Model | SP100 |

Number of axes | 6 |

Payload | 100 kilograms |

Reach | 2236mm |

Repeatability | 0.03 |

weight | 660 kg |

Power supply | 5 KVA |

Mounting options | Floor |

SP165-105

The MOTOMAN SP165-105 is a robot specifically designed for spot welding and handling tasks. With a reach of over 3 meters, it is ideal for tasks such as workpiece handling with a stationary welding gun. It can be used with various spot welding guns and technologies, including servo-controlled welding guns with robot-assisted gun balance.

Thanks to its slim design, this robot doesn’t require mechanical counterweight compensation. This allows for lower moving masses and enables higher accelerations and speeds. The stable wrist of the robot is especially suitable for quick and precise positioning movements, which are commonly needed in spot welding applications.

The MOTOMAN SP165-105 is powered by the compact and powerful MOTOMAN YRC1000 controller. It incorporates the latest Yaskawa Sigma7 servo drive technology, which ensures excellent dynamics and energy efficiency. As a result, the robot achieves impressive cycle times.

Model | SP165-105 |

Number of axes | 6 |

Payload | 105 kilograms |

Reach | 3058mm |

Repeatability | 0.05 |

weight | 1090 kg |

Power supply | 5 KVA |

Mounting options | Floor |

- The application possibilities of this system are flexible and diverse. It offers a wide range of uses due to its versatility.

- Despite having a long reach, this system occupies minimal space. It has a small footprint, making it suitable for compact environments.

- This system demonstrates impressive dynamics and repeatability. It can perform tasks with high speed and precision, consistently delivering accurate results.

- Additionally, this system excels in energy efficiency. It utilizes power effectively, optimizing energy consumption and minimizing waste.

SP150R

The MOTOMAN SP150R is a robust 6-axis robot designed for spot welding and handling tasks. It can be mounted on shelves and offers an extended working space below its installation level, making it suitable for downward work on structures such as steel.

With a maximum payload capacity of 150 kg (including C-adapter), it is compatible with various spot-welding guns and grippers. It particularly excels with servo-controlled welding guns, serving as an integrated 7th axis with robot-supported gun compensation.

Controlled by the compact and powerful MOTOMAN YRC1000 controller, the MOTOMAN SP150R incorporates the latest Yaskawa Sigma7 servo drive technology. This state-of-the-art technology ensures exceptional dynamics and energy efficiency, resulting in remarkable cycle times.

The robot offers the option of being mounted in an elevated position, opening up diverse application possibilities while maintaining a small footprint. It delivers impressive dynamics and repeatability, allowing for high-speed and precise movements. Moreover, it boasts high energy efficiency, utilizing power effectively and minimizing wastage.

Model | SP150R |

Number of axes | 6 |

Payload | 150 kilograms |

Reach | 3140mm |

Repeatability | 0.05 |

weight | 1760 kg |

Power supply | 5 KVA |

Mounting options | Shelf-Mounted |

SP165

The MOTOMAN SP165 is an advanced and versatile robot designed for standard spot welding and handling tasks. It has a payload capacity of 165 kg (including C-adapter) and is compatible with a wide range of spot-welding guns and technologies. It particularly excels with servo-controlled welding guns, aided by robot-assisted gun alignment.

Thanks to its slim design, this robot doesn’t require a mechanical counterbalance. It has low moving masses, allowing for higher accelerations and speeds. The stable wrist of the robot is well-suited for precise and rapid positioning movements commonly needed in spot welding applications.

Controlled by the compact and powerful MOTOMAN YRC1000 controller, the MOTOMAN SP165 incorporates the latest Yaskawa Sigma7 servo drive technology. This cutting-edge technology ensures exceptional dynamics and energy efficiency, resulting in impressive cycle times.

The robot offers versatile application possibilities due to its adaptability. Its slim design also minimizes its footprint, making it suitable for installations in tight spaces. It delivers outstanding dynamics and repeatability, enabling precise and consistent performance. Additionally, it excels in energy efficiency, utilizing power effectively while minimizing waste.

Model | SP165 |

Number of axes | 6 |

Payload | 165 kilograms |

Reach | 2702mm |

Repeatability | 0.05 |

weight | 1020 kg |

Power supply | 5 KVA |

Mounting options | Floor |

SP185R

The MOTOMAN SP185R is a robust 6-axis robot designed for spot welding and handling tasks. It can be mounted on shelves and offers an extended working space below its installation level, making it suitable for downward work on structures such as steel.

With a maximum payload capacity of 185 kg (including C-adapter), it is compatible with various spot-welding guns and grippers. It particularly excels with servo-controlled welding guns, serving as an integrated 7th axis with robot-supported gun compensation.

Controlled by the compact and powerful MOTOMAN YRC1000 controller, the MOTOMAN SP185R incorporates the latest Yaskawa Sigma7 servo drive technology. This state-of-the-art technology ensures exceptional dynamics and energy efficiency, resulting in remarkable cycle times.

The robot offers the option of being mounted in an elevated position, opening up diverse application possibilities while maintaining a small footprint. It provides flexibility in various industrial settings and occupies minimal space, allowing for efficient use of work areas.

Model | SP185R |

Number of axes | 6 |

Payload | 185 kilograms |

Reach | 3140mm |

Repeatability | 0.05 |

weight | 1830 kg |

Power supply | 5 KVA |

Mounting options | Shelf-Mounted |

SP210

The MOTOMAN SP210 is a high-performance robot designed for spot welding and handling tasks. With a payload capacity of 210 kg (including C-adapter), it is compatible with a wide range of spot-welding guns and technologies. It particularly excels with servo-controlled welding guns, benefiting from robot-assisted gun alignment.

Thanks to its slim design, this robot operates without the need for a mechanical counterbalance balancer. It has low moving masses, enabling higher accelerations and speeds. The stable wrist of the robot is well-suited for precise and rapid positioning movements commonly required in spot welding applications.

Controlled by the compact and powerful MOTOMAN YRC1000 controller, the MOTOMAN SP210 incorporates the latest Yaskawa Sigma7 servo drive technology. This cutting-edge technology ensures exceptional dynamics and energy efficiency, resulting in outstanding cycle times.

The robot offers versatile application possibilities, making it suitable for various industrial tasks. It has a high payload capacity while maintaining a small footprint, maximizing space efficiency. Additionally, it delivers excellent repeatability, ensuring consistent and precise performance.

Model | SP210 |

Number of axes | 6 |

Payload | 210 kilograms |

Reach | 3140mm |

Repeatability | 0.05 |

weight | 2702 kg |

Power supply | 3 KVA |

Mounting options | Floor |

SP235

The MOTOMAN SP235 is a high-powered robot designed for spot welding and handling tasks. It has an impressive payload capacity of 235 kg (including C-adapter) and is compatible with a wide range of spot-welding guns and technologies. It particularly excels with servo-controlled welding guns, benefiting from robot-assisted gun alignment.

Thanks to its sleek design, this robot operates efficiently without the need for a mechanical counterbalance balancer. It has low moving masses, allowing for higher accelerations and speeds. The stable wrist of the robot is well-suited for precise and rapid positioning movements commonly required in spot welding applications.

Controlled by the compact and powerful MOTOMAN YRC1000 controller, the MOTOMAN SP235 incorporates the latest Yaskawa Sigma7 servo drive technology. This cutting-edge technology ensures exceptional dynamics and energy efficiency, resulting in outstanding cycle times.

The robot offers versatile application possibilities, making it suitable for various industrial tasks. It boasts a high payload capacity while maintaining a small footprint, optimizing space utilization. Additionally, it delivers excellent repeatability, ensuring consistent and precise performance. Moreover, it excels in energy efficiency, utilizing power effectively and minimizing waste.

Model | SP235 |

Number of axes | 6 |

Payload | 235 kilograms |

Reach | 2710mm |

Repeatability | 0.05 |

weight | 1345 kg |

Power supply | 5 KVA |

Mounting options | Floor |

Summary

In this article, we have examined welding robots and their various types and components. Yaskawa is one of the best manufacturers of welding robots. Yaskawa produces its welding robots in three different series. In this article, we have reviewed the models of all three series of Yaskawa welding robots.

To receive a consultation, pricing information, and purchase Yaskawa welding robots or robotic welding cells, you can contact us right away. At TS Group, we offer the latest models of Yaskawa robots produced in Europe at the best prices. In addition, TS Group provides support services, programming, installation, and after-sales services.

If you are looking to automate your manufacturing line and stay ahead of your competitors, contact us.

Is T.S.Group Yaskawa’s representative?

In fact, no company currently represents Yaskawa in Iran. Some companies misuse this title and introduce themselves as Yaskawa’s representative in Iran to attract customers’ attention. For more information, please read the article “Yaskawa’s representative in Iran”.

TS Group does not introduce itself as Yaskawa’s representative in Iran, but our relationship with Yaskawa is direct and we receive technical support directly from Yaskawa.