Laser Cutting Robot

These robots are widely used in automotive industry lines. Laser cutting robot, laser welding robot and handling robots are some of the applications of Yaskawa robot in the automotive industry.

Pressing Robot

Yaskawa’s special pressing robots are ideal for pressing metal sheets with heavy cycles.

Packing Robot

The integrated robotic packaging solutions of Tajhizsanatrobot Group are designed and developed to meet the needs of customers.

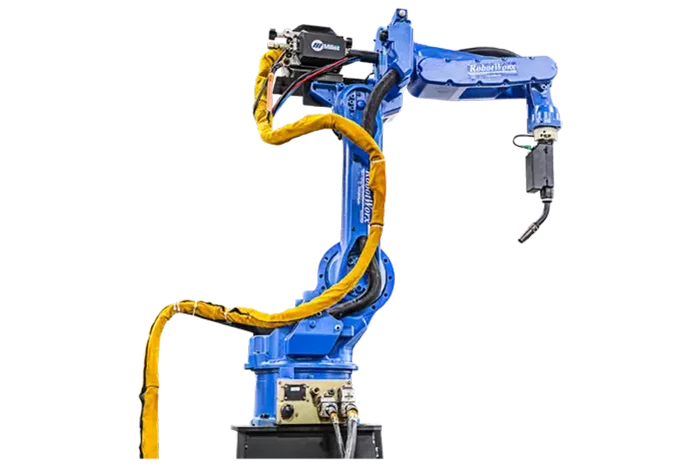

Welding Robot

These robots are widely used in automotive industry lines. Electric welding robot, spot welding robot and handling robots are some of the applications of Yaskawa robots in the automotive industry.

Palletizing Robot

TS Group Robot Co Tajhizsanatrobot Company provides manufacturers with a wide range of robotic solutions for palletizing and de-palletizing.

why T.S.Group ؟

The industrial group of the robot industry equipment

Industrial robots are produced in many types with many different options. On the other hand, the applications of industrial robots are very variable according to the work environment and hence robots need customization. Therefore, choosing the right robot is a challenge. The experienced specialists of the T.S.Group team are ready to provide advice and talk with you to understand your needs and concerns in order to provide suitable and special solutions for you.

Programming and optimal use of robots today may not be as complicated as in the past, but it is still a specialized expertise. But don’t worry about installing, programming and running your robotic cells. You can leave all these tasks to the specialists of T.S.Group.

Yaskawa robots are built for tough conditions and long-term use. However, if you need reconfiguration, update, repair and after-sales service, TS Group will always be by your side.

The TS Group team consists of enthusiastic, creative and experienced personnel who are committed to their work and the success of their customers.

At TS Group, we are ready to offer the latest models of Yaskawa robots produced in Yaskawa Europe. Yaskawa offers the latest robotics technologies in the field of industrial robot manufacturing worldwide.

We cooperate with well-known companies such as Nestlé, Sa-Iran, Zarmacaron, Zarkam, Salemin and many other successful companies. You can also join these reputable companies and use the services of T.S.Group.

شرکت تجهیز صنعت ربات تمامی موارد را در سایت خود توسعه می دهد، می سازد و مونتاژ می کند و با توجه به حضور تیم خدمات فنی مستقر در شرکت این امکان را داریم که در کوتاه ترین زمان ممکن خدمات و سرویس های مورد نیاز را به مشتریان خود ارائه دهیم.

- ما تیم خلاق هستیم

- تعهد کیفیت

- خدمات مشاوره ای کامل

- ما همیشه بهبود می یابیم

TS Group Robot Co

Our industrial group services

Yaskawa robot; The best option for automating all manufacturing stages

This is the age of robots. In the future, only industries that dare to use robots in their production line will be able to compete. just a few years ago, we didn’t think that robots would appear everywhere so soon. A high-quality robot doubles or even triples the productivity of the manufacturing line. The robot does not need to sleep, rest or meal breaks. They can work useful hours around the clock. Using robots eliminates human error and operator problems, and the list of advantages goes on… Among these robots are those that have pushed these boundaries and have capabilities that will surely convince you to use them.

As everyone knows, the Japanese are famous for their expertise in robotics. One of the largest and most successful industrial robot manufacturers in the world is the well-known Japanese company, Yasakawa. Yasakawa robots have many advantages and capabilities, which we want to take a closer look at in this article. We will also introduce some of the most popular and widely used types and models here.

in the T.S. Group team, we are ready to offer you all types of Yasakawa robots with the aim of increasing productivity, reducing production costs, and improving the safety and health of human resources.

Yaskawa robot

Yaskawa is one of the largest manufacturers of industrial robots, with installed over 540,000 robots worldwide. Yaskawa offers various types of robots based on their application, including welding robots, palletizing robots, painting robots, collaborative robots, and mobile robots.

Yaskawa factory in Europe

Yaskawa Electric Corporation was founded in Japan under the name Yaskawa in 1915. The company’s first robot was introduced to the market in 1977.

Yaskawa Robotics currently has major factories located in Europe, Canada, the United States, Mexico, and Brazil. Yaskawa’s robots are known for their high speed, precision, and maneuverability. Having 7 axes in single-arm robots and 15 axes in dual-arm robots provide high level of maneuverability for Yaskawa robots. Yaskawa employs the latest technology in their controllers, vision systems, and various components, providing high-quality solutions that meet the needs of their users.

YASKAWA – 7 robots / 45 axis system

Advantages of Yaskawa motoman robots

known as Motoman robots, Yaskawa’s products are among the most well-known names in the industrial robotics industry. Yaskawa is known for producing the best industrial robotic cells, robotics software, and accessories. Yaskawa robots can automate almost all production-related tasks, from robotic assembly to automatic material handling and welding processes. The advantages of Yaskawa Motoman robots include:

1. Automating the manufacturing process and increasing efficiency

Automating the manufacturing process with Yaskawa robots has numerous benefits and significantly increases your production capabilities. Yaskawa robots, also known as Motoman, operate at extremely high speeds without sacrificing precision. The increased operational speed allows more stages of the work to be accomplished in less time, which raises the efficiency rate.

2. Faster speed and efficiency

The speed of the Yaskawa robot’s work process exceeds that of human labor, but it’s not all. These robots do not face the work interruptions that humans do. They perform work stages without interruption or hesitation, or human distractions, which prevents delays in the production process.

While more stages of work are completed in less time, Yaskawa robots have longer working hours compared to human labor. With Yaskawa robots employed 24/7, productivity issues will be meaningless.

Automating an entire assembly line with the Yaskawa Motoman HP20 robot will increase the efficiency rate up to two or even three times.

pick and place Yaskawa motoman H20

3. Prevention of production errors

Yaskawa robots reduce production cycle time with high precision and speed. Production errors are significantly reduced because these robots perform programs exactly according to the programmed parameters.

4. revention of waste and scrap production

The exceptional accuracy and high level of repeatability in Yaskawa’s articulated robots prevents material waste. Elimination of waste reduces production time and cost, resulting in increased efficiency in the entire production process.

As Yaskawa robots perform various robotic functions, they reduce the number of components involved in the production process. By simplifying the production process Yaskawa robots increase production efficiency and effectiveness.

5. Flexibility in application type

The multi-functional capabilities of the Yaskawa robots enable flexible automation for manufacturers. For example, the Yaskawa Motoman HP50-20 robot can be programmed for pick-and-place operations, but in case there is any changes in manufacturing line in the future, the same robot can be used for tasks such as welding or material handling.

Yaskawa robot is an intelligent investment. These robots can always be reprogrammed quickly to adapt to changes. This is in contrast to hard automation robots, which are not flexible for reprogramming. Hard automation robots can only be used for a specific task.

The advantage of human workforce over a hard automation robot is that they can always be retrained for new tasks. However, the retraining process for human workers is time-consuming and requires trial and error until the learning is complete.

In contrast, Yaskawa robots do not require learning time and can be ready to work like an expert as soon as they are programmed. This feature is an added value to it’s flexibility of performing tasks.

Yaskawa robots also have the ability to integrate with robotic vision systems and AI. Integration with robotic vision systems enables dynamic and flexible adaptation to changes and provides even more flexibility for your production automation.

Even a used Yaskawa robot still has components and tools that can be integrated and the necessary flexibility for future and different uses.

6. Reliability

Another advantage of Yaskawa Motoman robots is their reliability. When competition is very close and the difference between competitors is very small, having a reliable production line is vital for companies. An unforeseen delay, error, or damage to parts will be very costly for manufacturers.

Yaskawa robots are built for long-term operation. Many older models of these robots, such as the Motoman HP6, are still in use in production lines.

New models of Yaskawa’s 6-axis robots are designed with internal wiring and cables to prevent unexpected wear and failures. This also makes maintenance easier and requires fewer inspections. Automatic troubleshooting software and calibration devices help Yaskawa robots stay in optimal conditions. All these features are designed and predicted to ensure reliable performance, high-quality product manufacturing, and uninterrupted production for Yaskawa robot users.

Types of Yasakawa robots and their applications

The automation of production processes and the use of robots began in large industries such as automotive and welding in the 1970s. Yasakawa has also been present in this market from the beginning. Today, with the advancement of technology and the availability and affordability of robots, robots are used for production automation in various industries and for various applications. Robots today increase productivity and improve the health and safety of human labor especially in welding, handling, packaging, pressing, machining, polishing, and other applications. In the following, we will discuss some of the applications of Yasakawa industrial robots.

1. Yasakawa Handling Robot

Handling materials has always been a repetitive and harmful task for human labor in manufacturing lines. The most important reason for producing robots is precisely to perform these repetitive activities and prevent harm to human labor. However, this is not the only advantage of the Yasakawa handling robot. Handling robots can work around the clock and 24/7.

Before purchasing a Yasakawa handling robot for your production automation, you should consider some features. These features include the weight of the load to be moved, the required speed, the final gripper or end-effector that will pick up the desired object, the installation space of the robot, and possible problems. By considering these features, you should choose your handling robot model from among Yasakawa’s robot series designed for various workspace features.

Yaskawa produces four series of handling robots for various features of your workspace.

2. GP Series

These multifunctional robots have 6 axes. The payload is from 4 to 600 kilograms. These robots can also be programmed for assembly and machining. This series has a wide variety of 36 different models, each with different payload capacity and access range.

Mini robots of Yaskawa

3. MotoMINI Series

Specifically designed for handling and assembling small parts and part feeding operations, MotoMINI is the smallest six-axis high-speed robot series from Yaskawa.

This series of Yaskawa robots has only one model with a payload capacity of half a kilogram and a working range of 350 millimeters.

4. SDA Series

This series is very slim and agile. Yaskawa’s SDA series has two humanoid-like arms with a total of 15 axes. This series has 4 different models with different payload and access range.

5. SIA Series

Yaskawa’s SIA series, with its slim body and 7 axes, is capable of moving loads from 5 to 20 kg. With these features, this series provides superior dexterity and motion flexibility. In addition to handling, these robots can be programmed for assembly, inspection, and machining. Having 7 axes allows this robot to move its elbows while the wrist is still.

This series has three different models with different payload and renge.

New YASKAWA MOTOMAN robots at Automatica 2016, Germany

5. Packaging

Packaging or pick-and-place is one of the applications of Yaskawa robots. The task of the packaging robot is to sort, store, or pack products in a designated location such as moving them from conveyors into boxes, cartons, and bags. With the addition of vision and A.I systems, these robots can also perform more challenging tasks such as inspection.

Yaskawa packaging robots are offered in three series: SG, MPP, and MPK. These robots have exceptional speed and repeatability accuracy.

6. palletizing

These kinds of robots are designed for placing products, boxes, bags, or cartons from the conveyor belt onto pallets and empty the pallets. This task can be very damaging to human labor and their spinal column, especially at high heights. Various 6-axis robots of Yaskawa are suitable for palletizing and other applications. However, the PL series, which has 4 axes, is specifically designed for palletizing. Various types of Yaskawa PL series robots are offered with a useful payload range from 2 to 800 kg and a reach range of up to 3150 millimeters.

Yaskawa palletizing robot

7. Welding

Welding is one of the earliest and most important applications of industrial robots worldwide. It’s no wonder, due to eye damage and respiratory system damages caused by gases emitted from the welding process in closed production lines. The repetitive nature of the work process is also a factor that makes robots a necessary alternative for human labor. Furthermore, robots can perform welding more accurately and cleanly.

The welding process by Yaskawa robot is performed by different methods of electronic arc welding, spot welding, resistance welding, TIG, MIG, plasma and laser.

AR series of Yaskawa are specially designed for welding.

Yaskawa welding robot

8. Pressing Robot

In the United States alone, 368 cases of injuries caused by pressing machines are reported annually. Working with a pressing machine is highly dangerous and causes many cases of limb amputation each year. Therefore, using a pressing robot instead of a human operator is a very logical and reasonable decision. The task of pressing robots is to place metal pieces and sheets inside the machine at the proper angle for applying pressure and proper shaping. Another task of these robots is moving parts to press machine, move the finished product from the machine, and store them in the warehouse.

Yaskawa’s EP, GP, PH, and MH series robots are suitable for working with pressing machines and CNC.

Yaskawa’s pressing robot

9. Cutting Robot

Pressing machines or CNCs cannot perform delicate, geometric, or three-dimensional cuts very well. The best way to create such cuts is to use a robot. Robotic cutting is performed in various types, including plasma cutting, water jet cutting, spindle motor cutting, and laser cutting are some of the industrial cutting types can be done with a robot.

Yaskawa’s GA series robots are specialized robots for industrial cutting operations.

10. Machining Robot

A machining robot can be a suitable alternative for manual milling, CNC, and lathe machines. Industrial machines cannot work on very large parts, and they lack flexibility and sufficient access. In contrast, robots can perform all of these tasks. A machining robot can work on different materials such as wood, plastic, composite, fiberglass, stone, graphite, foam, and metal.

11. Assembly Robot

Today, robots are used for assembling parts on various manufacturing lines. Assembly robots with a higher payload are used in automobile production lines, while smaller and more agile robots are used for assembling electronic components and boards, such as mobile phones and computers.

assembly Yaskawa robot cell

Given the repetitive nature of assembling and the high speed and precision of robots, it is the best option to use robots in order to increase production efficiency.

The 6-axis GP series from Yaskawa are suitable for assembly work. Additionally, 7-axis SIA robots have more capabilities in narrow and confined spaces.

Yaskawa assembly motomini robot

12. Paint Spraying Robot

Spray Painting can be extremely harmful to the lungs of human workers. In addition, you cannot expect consistent and clean work that you would expect from a robot from human workers.

Yaskawa paint spraying robot

Popular Models of Yaskawa Robots

GP Series

You may have heard of the Motoman GP12 or GP25 robots. These are two top models of Yaskawa’s versatile GP series robots. GP series robots, with a payload capacity ranging from 4 kilograms to 600 kilograms, can be used to handle materials from light to heavy.

Aside from transporting materials, Yaskawa GP series can also perform tasks such as arc welding, spot welding, material dispensing, and material removal. Due to their popularity, many of these industrial robots can be found as second-hand in the market, which makes them a cost-effective automation solution.

AR Series

Yaskawa’s Motoman robots are well-known for their arc welding robots, and one of their top series is the AR series. These 6-axis arc welding robots are truly masters of their craft, with high speed, efficiency, and quality. By using the Motoman AR1440 in the production line, cycle time is significantly reduced. Their simple design makes welding in narrow and tight spaces possible and easy. The AR series robots are among the most advanced robots in their class.

SP Series

Yaskawa’s robot series SP is specifically designed for spot welding and material handling processes. These robots have a payload ranging from 80 to 280 kilograms, making them suitable for lifting medium to heavy loads. The Motoman SP165 is one of the most popular robots in this series due to its high speed and accuracy, which reduces production cycle time while increasing quality. As a result, the SP series robots have been very successful for Yaskawa.

MH series

Motoman MH50 and MH6, as part of the MH series, are other outstanding examples of one of the greatest industrial robot manufacturers. These robots cover a wide range of production needs, from light-duty to heavy-duty tasks, making them suitable for various industries. Most robots in this series use the Motoman DX100 or DX200 controller. The payload for this series can vary from 3 to 600 kilograms. These robots can automate tasks such as assembly, machine tending, and packaging programs.

EA Series

The EA series is one of the old lines of Yaskawa’s arc welding robots. These robots are now mainly sold in the second-hand robot market, but are still as popular as ever. This series of Yaskawa robots became famous with the models Motoman EA1400N and EA1900N. These robots provide high operation speed for light loads and reduce production cycle time. Robots in this series use the Motoman NX100 or XRC controller. The productivity of the production line can be increased by integrating these robots with the Motoman ArcWorld welding cell.

HP Series

The HP series of Yaskawa includes the popular Motoman HP20 and HP165 robots. These robots can automatically perform material handling, distribution, and cutting with their high precision. These models can be used in various ways along production lines, including wall, ceiling, and floor installation. HP series robots provide fast, flexible, and accurate automation for various industries.

Yaskawa robots are used in different ways such as installation on the ground, walls, and ceiling. Ceiling installation not only increases robot accessibility but also allows for a much better and cost-effective use of workshop or factory space.

Conclusion:

If you also have a factory or production line and care about the progress, productivity, and human resource health of the industry and trade, Yaskawa robots will be the best option for you. T.S.Group is ready to offer various new Yaskawa robots, robot cells and solutions for any application for your manufacturing lines. We also offer consultation and after-sale services. We are looking for long-term collaboration with our partners.

To receive consultation for choosing the desired robot cell, please call the number below.

Is T.S.Group Yaskawa’s representative?

In fact, no company currently represents Yaskawa in Iran. Some companies misuse this title and introduce themselves as Yaskawa’s representative in Iran to attract customers’ attention. For more information, please read the article “Yaskawa’s representative in Iran”.

TS Group does not introduce itself as Yaskawa’s representative in Iran, but our relationship with Yaskawa is direct and we receive technical support directly from Yaskawa.

میانگین هزینه یک ربات یاسکاوا موتومن دستهدوم با کنترلر بهروزشده در حدود 17,500 دلار است.

هر تولیدکنندهی ربات از زبان برنامهنویسی مخصوص خود استفاده میکند. رباتهای یاسکاوا از زبان برنامهنویسی INFORM 2 استفاده میکنند.

ربات دکارتی

ربات اسکارا

ربات مفصلی

ربات استوانهای

ربات دلتا

ربات قطبی (دارای مفصل دورانی)

ربات همکار انسان cobot

رباتهای صنعتی یاسکاوا موتومن که شرکتی ژاپنی است رباتهای خوشساخت و بسیار قابلاعتمادی هستند. بهدلیل همین کیفیت بالا این رباتها میتوانند برای سالها و حتی دههها کار کنند. خرید یک ربات موتومن MA 1440 استفاده شده یا هر مدل یاسکاوای دسته دوم دیگر به اندازه یک ربات نو قابل اعتماد است.

یاسکاوا الکتریک یک شرکت ژاپنی است اما کارخانههای ساخت ربات یاسکاوا در ژاپن، چین، آمریکا و در اروپا واقع شدهاند.

روبات یاسکاوا برای اهداف توزیع خودکار، برش، دریل، آسیاب، خردکردن، پالتگذاری، بستهبندی، جوشکاری، عملیات گذاشت و برداشت، رنگپاشی و موارد دیگر مورد استفاده قرار میگیرد. هر کاری در خط تولید را میتوانید با استفاده از رباتهای یاسکاوا بهصورت خودکار درآورید.

More resources and content:

Yaskawa Motoman: Industrial Robots & Robot Automation Tech

MOTOMAN Robots – Yaskawa Europe

Yaskawa Europe – Your First Choice for Automation

Popular Yaskawa Robot Models

Advantages of Yaskawa Motoman Robots

Yaskawa Benelux: Uw partner voor industriële automatisering

Yaskawa America Inc. Home – Yaskawa

Frequently asked questions

Yaskawa Motoman robots are utilized by automakers not just for arc and robotic spot welding, but also for tasks like assembly, painting, material removal, and material handling. The electronics industry also frequently employs Yaskawa Motoman six-axis robots for their automation requirements.

Yaskawa Motoman robotic arms for industrial use are constructed to a high standard and are incredibly dependable, allowing them to function for many years, if not decades.

there is no company that officially represents Yaskawa in Iran at the time. However, some companies falsely claim to be Yaskawa's representative in Iran to lure customers. To learn more about this, refer to the article "Yaskawa's representative in Iran".

TS Group, on the other hand, doesn't present itself as Yaskawa's representative in Iran, but our connection with Yaskawa is direct and we receive technical assistance directly from them.